Showing 97–108 of 189 results

-

- High-Precision UV-VIS Quartz Windows for Optical Applications

- Custom UV-VIS Quartz Windows – Superior Clarity & Durability

- Premium UV-VIS Quartz Windows | High Transmission & Custom Sizes

-

Key Takeaways

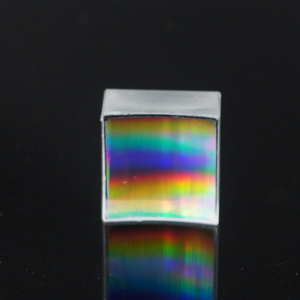

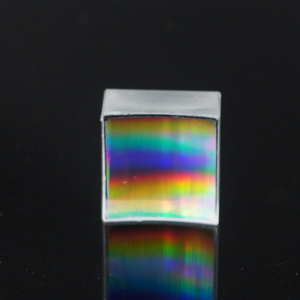

- Optical coatings, including High Reflective Coatings and dielectric coatings, are thin films applied to optical components to control their reflectance and transmittance properties.

- These coatings work by interfering with light waves, resulting in constructive or destructive interference depending on the coating thickness and the wavelength of light.

- Metallic coatings, such as High Reflective Coatings, offer high reflectance over a wide range of wavelengths, while dielectric coatings provide lower reflectance but can be tailored to specific wavelengths.

- Optical coatings find widespread applications in various industries, including lasers, telescopes, cameras, and medical devices, due to their ability to enhance optical performance.

-

- Excellent Transmission from 0.12 to 7μm

- Rugged and Durable

- Resistant to Chemical Etching

-

Size:4mm-300mm+0.0/-0.1mm

clear aperture:>90°

Surface quality:10/5!80/50

Tolerance:±0.1mm

Parallelism:10arc sec~3 arc min

Beveling:0.2mm×45°

AR coating or custom design

-

- Material: Optical glass

- Surface quality: 20/10 – 80/50

- Diameter tolerance: 0.0/-0.1mm

- Wedge angle: < 1 arcmin

- Surface flatness: Lambda/10 ~ Lambda/4

-

- Substrate: BK7

- Surface Quality: 40-20

- Power (P-V) @ 632.8nm: 1.5λ

-

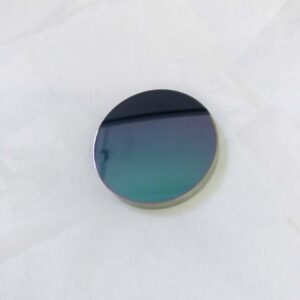

The Infrared Germanium window is widely used optical components designed for applications in the mid-infrared (IR) spectrum. With excellent transmission from 2 μm to 14 μm, germanium window is a preferred choice for infrared imaging, thermal cameras, and spectroscopy systems. Its high refractive index and durability make them one of the most important materials in…

-

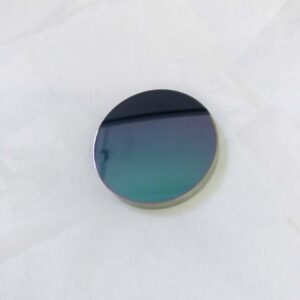

Silicon (Si) optics are primarily used in the 1.1- 7μm range. Silicon is ideally suited for weight sensitive applications having a Density of 2.329 g/cm3

Silicon is typically used in the 3 – 5μm for Thermal Imaging Systems

- Transmission from 1.1 – 7μm

- Available AR/AR and AR/DLC Coated for 3 – 5μm

- Custom coatings are available on request

-

-

- Material: BK7/K9,ect.

- Clear Aperture: >90%

- Parallelism: <3 arc min

- Dimension Tolerance: +/-0.1

- Surface Quality: 60/40

- Clear Aperture: >90%</li>

-

- Corning 7979 IR Grade Fused Silica Substrates

- Broad Transmission Range from 200 – 3500nm

- λ/10 Transmitted Wavefront Distortion

- Excellent Thermal Stability

-

- High Transparency: Provides a clear and elegant view of the watch dial.

- Scratch Resistant: Made from durable materials to prevent scratches.

- Luxury Appeal: Enhances the watch’s aesthetic and value.

-

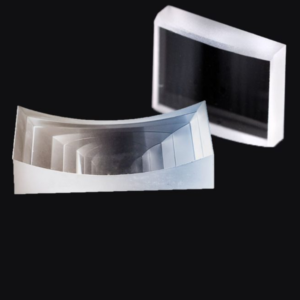

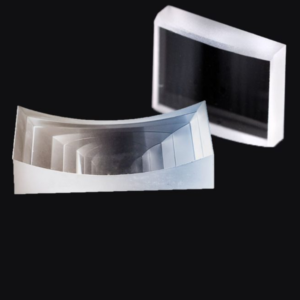

- Ideal for Applications Requiring Magnification in One Dimension

- Provide Anamorphic Shaping of Images

- Used to Transform a Collimated Beam into a Line