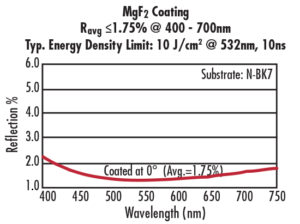

MgF2 Coated Double-Concave (DCV) Lenses

- Wavelength Range (nm): 400 – 700

- Surface Quality: 40-20

- Coating: Optional

Specifications

| MgF2 | |

| Diameter Tolerance: | +0.0/-0.1mm |

| Surface Quality: | 40-20 |

| Center Thickness Tolerance: | ±0.2mm |

| Bevel: | 0.2mmX45° |

| Coating: | Optional |

Double-Concave (DCV) lenses are optical lenses with two inward-curved surfaces, designed to diverge collimated light beams.

They feature a negative focal length, making them ideal for applications requiring beam expansion, control of optical magnification, or correction of optical aberrations.

When coated with MgF₂ anti-reflection coatings, they achieve significantly higher transmission by reducing surface reflections across the UV–visible–near-IR spectrum.

Properties of a Double Concave Lens

A double concave lens (DCV lens) is a type of diverging lens with both surfaces curved inward (concave). It has distinct optical properties:

Shape and Structure

- Both sides are concave.

Optical Behavior

- Diverging effect: Parallel incoming light rays spread outward after passing through.

- Forms virtual, upright, and reduced images when used alone.

- Has a negative focal length.

Focal Length

- The focal point is virtual, located on the same side of the lens as the light source.

Applications of MgF₂ Coated DCV Lenses

- Beam Expansion Systems:

- Optical Instruments:

- Laser Applications:

- Scientific Research:

- Medical Devices:

Why Choose MgF₂ Coated Double-Concave Lenses?

- MgF₂ coatings provide superior transmission and reduced reflection losses.

- Suitable for UV, visible, and near-IR applications.

- Hard MgF₂ coating resists environmental degradation.

- Available with alternative coatings (e.g., broadband AR, V-coating) to suit specialized wavelength ranges.

Chenyu experienced design team provides customers with support for optical system design, covering the entire process from initial design to prototype development and production.

You can consult with our staff if you are interested.