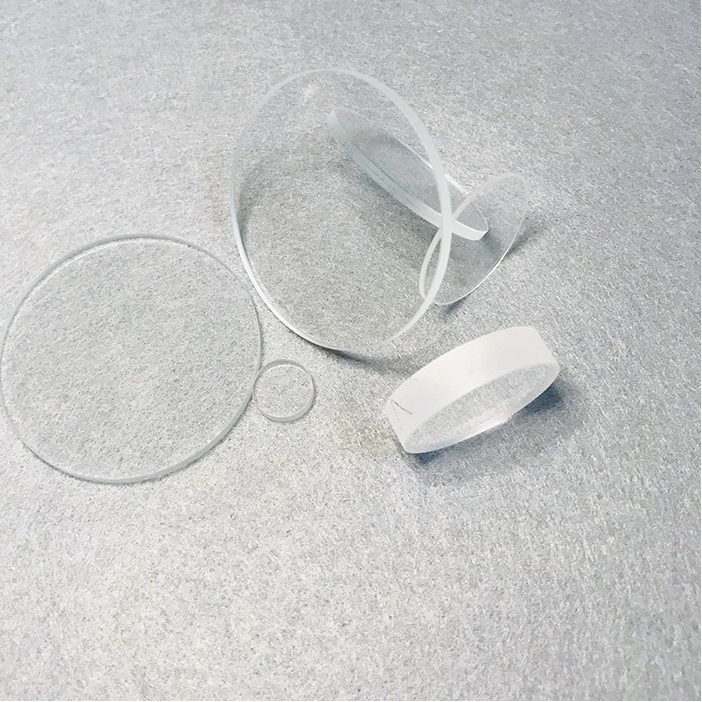

Customizable Laser Optial Glass Windows

- Transmittance: ≥ 99.5% (after AR coating)

- Surface Quality: 10-5 / 20-10 (MIL-PRF-13830B)

- Flatness: λ/10 or λ/4 @ 633 nm

- Clear Aperture: ≥ 90% (in diameter)

- Surface Roughness: < 5 A (atomic level)

- Thickness tolerance: ±0.1 mm or stricter

Commonly used materials include fused quartz, sapphire, calcium fluoride, zinc selenide, etc.

It is suitable for various wavelength bands ranging from ultraviolet to mid-infrared (150 nm to 16 μm).

Therefore, people often use them in laser cutting, medical, scientific research and infrared detection fields. It can be customized with coatings and sizes according to customer requirements.

Advantages of Laser Window

-

High Transmission

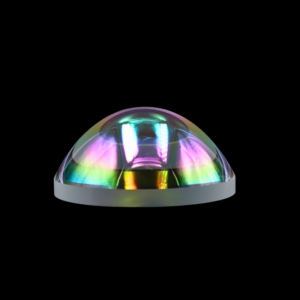

The laser window has undergone professional coating treatment. It has extremely high transmittance in specific laser wavelengths (such as 1064nm, 532nm, 10.6μm, etc.), usually reaching ≥ 99.5%, minimizing energy loss to the greatest extent.

-

High Laser Damage Threshold, LIDT

It can withstand high-power laser irradiation without cracking, ablation or thermal failure. Therefore, the laser window is suitable for high-power laser devices. No matter in what environment, it can provide a secure guarantee for the components.

-

Precise optical surface quality

Surface quality typically reaches: 20 – 10 or 10 – 5 (in accordance with MIL-PRF-13830B standard).

The flatness can reach λ/10 @ 633 nm, ensuring low wavefront distortion.

Effective light aperture is ≥ 90%

-

Extensively application:

-

- Industrial laser processing equipment (marking, welding, cutting)

- Medical lasers (laser knives, laser beauty treatments)

- Research instruments and vacuum chambers

- Infrared thermal imaging window

- Laser ranging and communication system

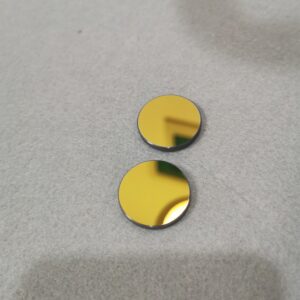

Material of laser window

The laser window requires the use of materials with high transmittance and good heat resistance. Therefore, for high transmittance laser window , materials such as fused quartz or sapphire are required for the laser machine.

Chengyu selects high-purity materials. After deep polishing, we use high-quality laser machines to fuse quartz and sapphire, ensuring that each laser window plate is superior to those of other brands on the market.