What are Aspherical Lenses?

Aspherical lenses are optical components with a non-spherical surface curvature, meaning its radius of curvature changes across the lens surface.

This unique design addresses a critical limitation of spherical lenses: optical aberrations.

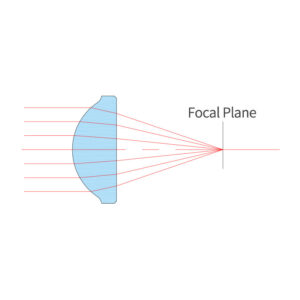

The advantage of aspherical lenses is that they can correct spherical aberration.

Spherical aberration is an optical effect that causes the incident light to focus at different points when forming an image, thereby resulting in blurriness.

Therefore, in most cases, people also choose aspherical lenses in order to enhance the accuracy of the image.

Why choose Aspherical Lenses?

Using aspherical lenses can reduce the common spherical aberration found in spherical lenses.

Aspherical lenses are designed with a variable curvature that deviates from the simple spherical shape, allowing them to effectively eliminate spherical aberration.

This ensures that light rays converge at a single focal point.

Therefore, it results in sharper images, higher resolution, and improved overall optical performance compared to traditional spherical lenses.

Here is the comparsion of the aspherical lens and spherical lens:

| Parameter | Spherical Lens | Aspherical Lens |

|---|---|---|

| Spherical Aberration (RMS wavefront error @ f/1.5) | ~0.2 – 0.5 λ | < 0.05 λ |

| Imaging Resolution (MTF @ 50 lp/mm) | ~0.4 – 0.6 | ~0.8 – 0.95 |

| Spot Diameter (focused, relative to ideal) | Enlarged by 30–50% | Close to diffraction limit (<10% deviation) |

| Encircled Energy (80%) | ~50–60% | >85–90% |

| Number of Lenses Required (to correct spherical aberration) | 2–3 spherical lenses | Single aspherical lens |

The substrate of the aspherical lens

Also, different types of materials are suitable for different scenarios. Here are some common substrate materials:

| Material | Features |

|---|---|

| N-BK7 Optical Glass | Low cost, excellent visible transmission, widely used standard optical glass |

| Fused Silica (UVFS) | High UV transmission, high laser damage threshold, excellent thermal stability |

| Calcium Fluoride (CaF₂) | High transmission from UV to IR, low dispersion |

| Magnesium Fluoride (MgF₂) | Excellent UV performance, high hardness |

| Sapphire | High strength, heat resistant, scratch resistant, suitable for harsh environments |

| Germanium (Ge) | Infrared material, transmission range 2–12 µm |

| Silicon (Si) | Mid-IR 1.2–7 µm, lightweight, high thermal conductivity |

| Zinc Selenide (ZnSe) | Suitable for CO₂ lasers (10.6 µm), common IR material |

| PMMA (Acrylic) | Low cost, lightweight, widely used in consumer optics |

| Polycarbonate (PC) | High impact resistance, suitable for molded optics |

| COP/COC | Low birefringence, suitable for precision molded aspheres |

Click here to view our aspherical lens products

Conclusion

By understanding their principles, types, and selection criteria, you can design or choose systems that deliver superior imaging, smaller size, and lower long-term costs.

Chenyu supports the customization and production of aspherical lenses. We use high-quality materials to provide you with superior lens products.

Therefore, if you need it, please contact with our staff.